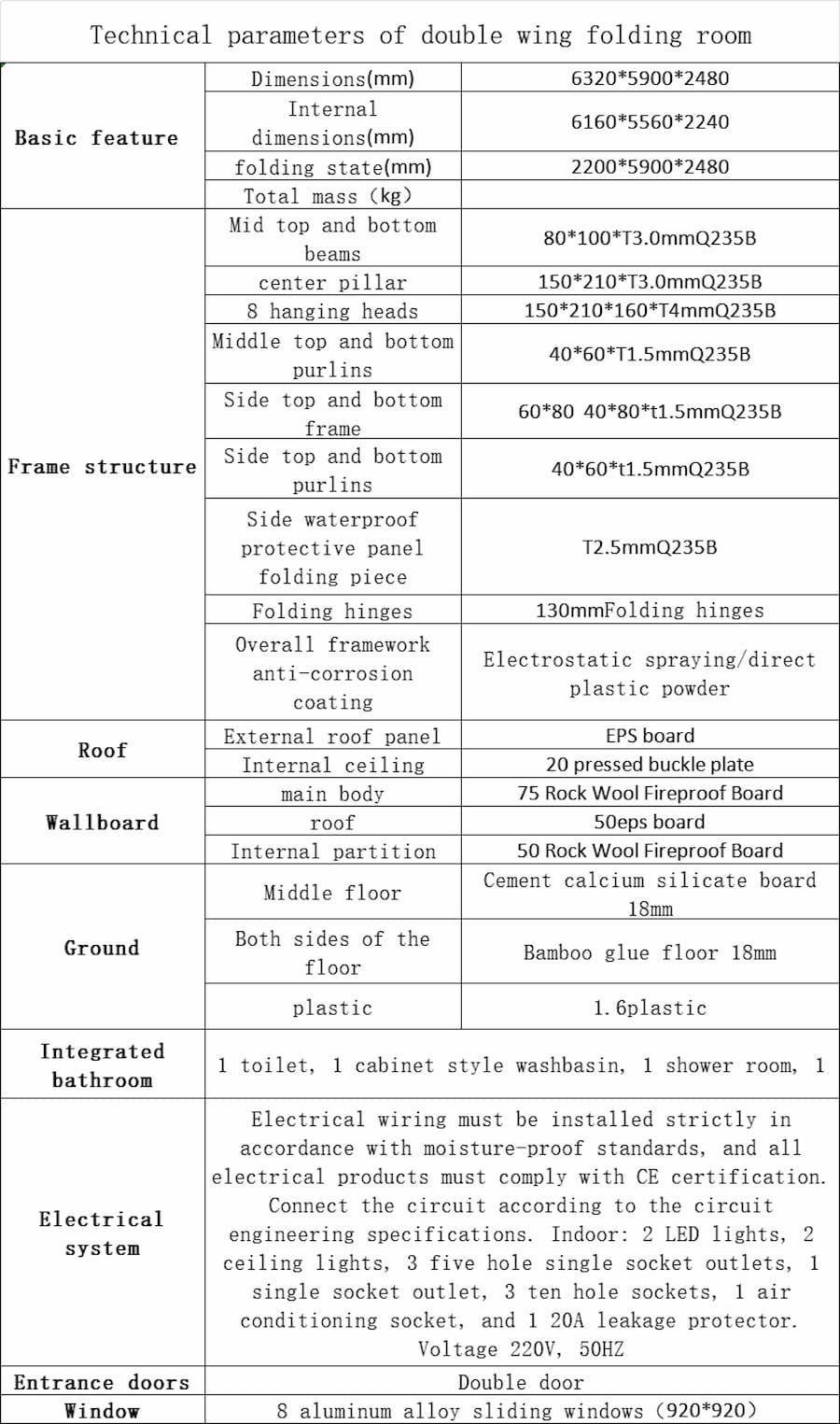

-

kilometer north of Hongde Logistics Park in Economic Development Zone, east of the road

kilometer north of Hongde Logistics Park in Economic Development Zone, east of the road

Packing box house is an environmentally friendly and economical mobile house with light steel as the skeleton and sandwich panels as the enclosure material. It is spatially combined through a standard modular series, with components connected by bolts, and has convenient assembly and disassembly functions.

Shipping Port :

Qingdao PortProduct Origin :

Weifang, Shandong, ChinaPayment :

EXW FOBThe packaging box room we provide is an advanced product that can be quickly assembled, moved, sturdy and durable, with sound and heat insulation. Using light steel structure as the skeleton material, our packing box house has excellent strength and stability. We use high-quality light steel materials to ensure the durability and reliability of our products.

The assembly of the packing box room is very fast and simple, without the need for complex construction processes, reducing construction time and costs. This means that you can quickly build the space you need, whether it's for temporary accommodation, office space, construction site office, or other purposes.

Our packaging room is exquisitely designed and has excellent mobility. You can easily dismantle and move it to other locations according to your needs without additional construction and renovation. This flexibility makes the packing box room an ideal choice for temporary or mobile needs, whether for temporary living or as a movable office space.

In addition, the packing box room has excellent sound and heat insulation performance, which can effectively reduce noise and heat transfer. This means you can find a peaceful and comfortable environment within it, whether it's in hot summer or cold winter.

We are committed to providing our customers with high-quality packaging box products. Through innovative design and advanced manufacturing processes, we ensure that every detail meets the highest standards. Our packing box room is suitable for various application scenarios, whether it is short-term use or long-term investment, it can meet your needs.

practical cases:

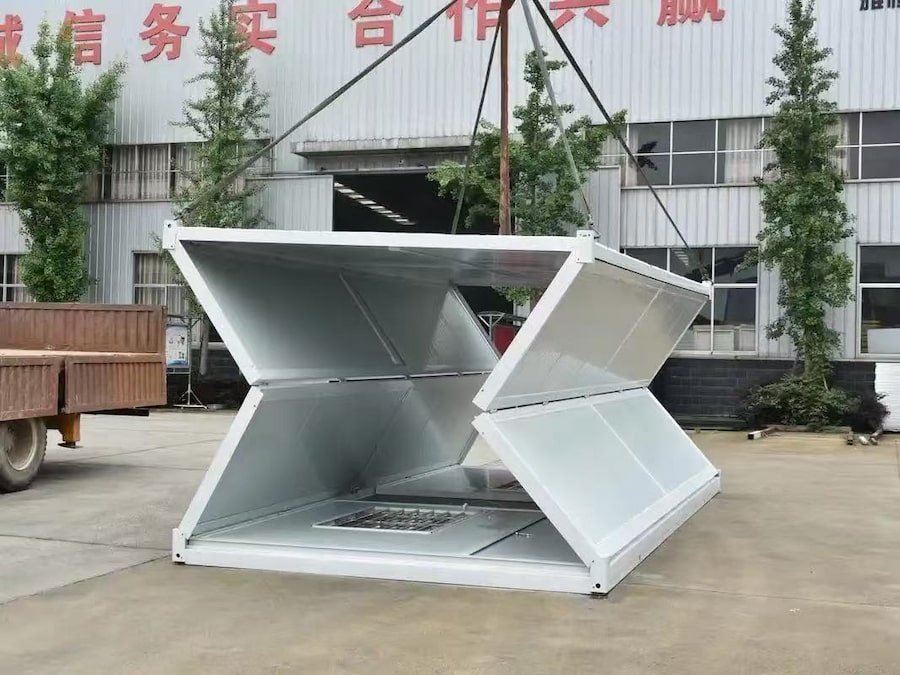

Double wing expansion box:

Assembly process framework assembly:

Connect prefabricated frame components such as bottom beams, top beams, and columns together by bolts or welding. When connecting bolts, they should be installed in the correct position according to the design requirements, and gaskets should be placed properly. There should be no missing or incomplete installation; The on-site welding of components should be accurate, without false welding or missed welding.

Wall and roof panel installation:

Install the pre made wall panels and roof panels onto the frame. Cut the door and window openings according to the designated positions on the design drawings using a cutting machine, and then install the plastic steel windows. For wall panels, it is necessary to ensure that they are installed firmly and sealed well, such as using wall panel buckles or slots for connection, to ensure the integrity and stability of the wall.

Installation of internal facilities:

Installation of water and electricity pipelines: Install water and electricity pipelines in the container room according to the design plan. The laying of pipelines should be arranged reasonably to avoid mutual interference, and the connection should be firm to prevent problems such as water leakage and electric leakage.

Ceiling installation:

For the bottom level ceiling work, such as using V831 color steel ceiling, it is necessary to ensure that the ceiling is flat, not sunken, and has good sealing performance such as insulation, cold resistance, and noise reduction during installation.

Surface treatment and debugging: During on-site welding and transportation, if the primer of the packaging box room peels off, it should be repainted with one layer of anti rust paint, and the exposed parts of the components should be painted with two layers of topcoat. The paint should not be missed, peeled, hung or rusted, in order to improve the appearance and rust prevention ability of the box room.

Function debugging:

Debugging the installed doors and windows to ensure flexible switching and good sealing; Test the water and electricity facilities to check if they are operating normally.

Hot Tags :